Room silencing, vibration reduction, vibration and noise measurements

Room silencing, vibration reduction, vibration and noise measurements

Due to their high-speed rolls, rotary printing presses cause vibrations in the machine and its foundation. Therefore, a large concrete foundation is often built to minimise settling and torsion of the machine. In case of poor soil conditions, the foundation is usually placed on piles. Even with the foundation placed on piles, settling can still occur from inadmissible vibrations being transferred from the machine, through the foundation, to the piles.

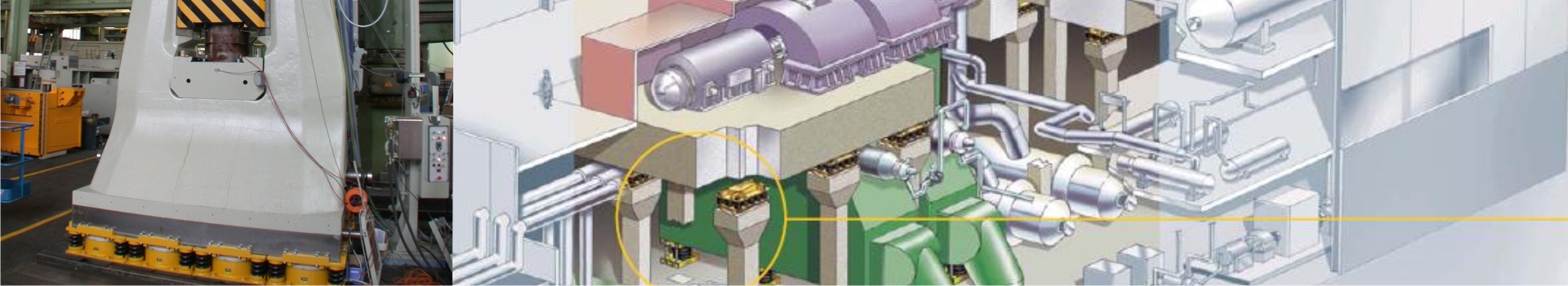

In order to avoid these effects, it is necessary that the machine and the building itself can be dynamically uncoupled by means of an elastic support. GERB spring units in combination with Viscodampers® are especially well suited for this:

- Highly elastic springs uncouple the machine from the substructure leaving the subsoil only statically loaded. Settling caused by machine vibrations is ruled out.

- Settling - caused externally - can be quickly and easily counteracted with GERB spring elements.

- GERB spring elements and Viscodampers® provide an excellent protection against earthquakes.

- Smaller printing machines can be mounted directly on a spring supported steel frame.

- The transfer of structure-borne noise is prevented by the dynamic uncoupling of the machine from the building itself. Therefore, the noise level caused by the machine is reduced in the adjacent rooms.

- The accelerations in elastically supported printing machines have been proven to be lower than with conventionally supported systems leading to lower wear and tear.

Contact us for more information.